In the world of industrial systems, hermetic feedthrough plays a crucial role in ensuring the integrity and efficiency of various processes. Designing these feedthroughs requires careful consideration of a variety of factors in order to achieve optimal performance and reliability. In this article, we will explore the key design considerations that engineers and designers must keep in mind when developing hermetic feedthroughs for industrial applications.

What is a Hermetic Feedthrough?

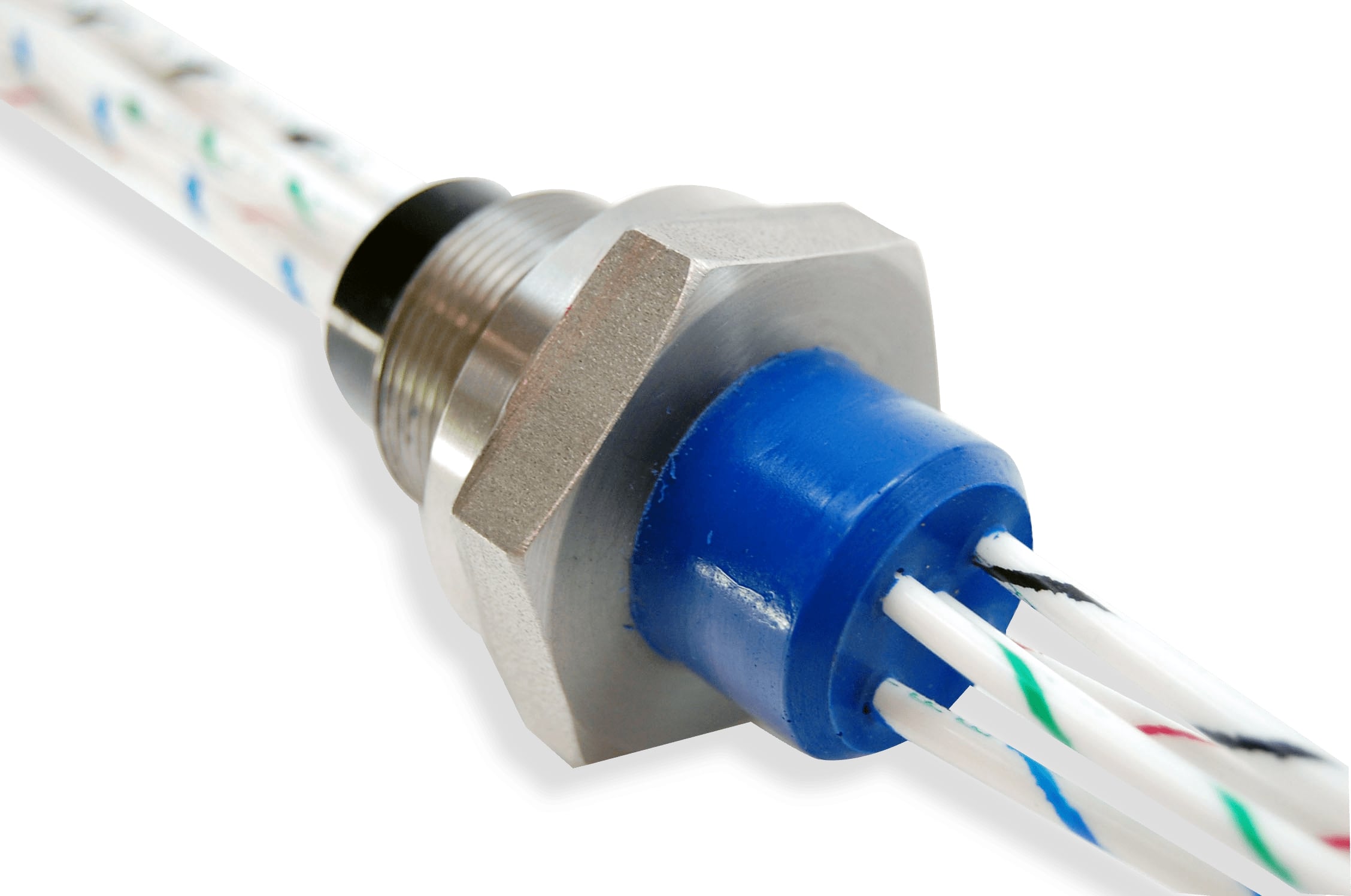

Before diving into the design considerations, let’s first understand what exactly a hermetic feedthrough is. A hermetic feedthrough is a component that is used to pass electrical signals, fluids, or gases from one environment to another without allowing any leakage. These feedthroughs are crucial in industrial systems where maintaining a controlled environment is essential for the overall operation.

Key Design Considerations

- Material Selection: One of the most important considerations when designing a hermetic feedthrough is the selection of materials. The chosen materials must be able to withstand the specific conditions of the industrial environment, such as temperature fluctuations, corrosive chemicals, or high pressures.

- Sealing Technique: The sealing technique used in a hermetic feedthrough is critical to ensuring a reliable seal that will prevent any leakage. Common sealing techniques include glass-to-metal seals, ceramic seals, and epoxy seals, each with their own pros and cons.

- Electrical Performance: For feedthroughs that are used to pass electrical signals, it is crucial to consider the electrical performance of the component. Factors such as signal loss, impedance, and insulation resistance must be carefully evaluated during the design process.

- Mechanical Integrity: In industrial systems where feedthroughs are subjected to mechanical stress, such as vibration or thermal expansion, the mechanical integrity of the component is paramount. Ensuring that the feedthrough can withstand these stresses without compromising its performance is essential.

- Environmental Considerations: Industrial environments can be harsh, with conditions such as high temperatures, humidity, and exposure to chemicals. Designing a hermetic feedthrough that can withstand these environmental factors without degradation is key to long-term reliability.

Conclusion

In conclusion, designing hermetic feedthroughs for industrial systems requires a thorough understanding of the various factors that can impact performance and reliability. By carefully considering material selection, sealing techniques, electrical performance, mechanical integrity, and environmental factors, engineers and designers can develop feedthroughs that meet the unique needs of industrial applications. By following these key design considerations, manufacturers can ensure that their industrial systems operate efficiently and reliably for years to come.

Learn about the essential design considerations for hermetic feedthrough in industrial systems, including material selection, sealing techniques, and environmental factors.

By incorporating these design considerations, designers can create hermetic feedthroughs that enhance the performance and reliability of industrial systems.

More Stories

The Role of Technology in Scenic Fabrication

Things you must know before becoming an insurance agent

Expert Professional Services Tailored to Your Unique Needs